-

Standard Stabilizer Clamp, Black, 1.5 Inch ID

FREE deliveryThis fits our 1.5 Inch Tie Rods – for all model steering stabilizers that use an OE style mounting system with 1/2” bolt.

Black powder coated DOM steel.

None

None

None$104.97$113.77FREE delivery -

Fox ATS Stabilizer Clamp, Zinc, 2 Inch ID

FREE deliveryThis fits our 2 Inch Tie Rods – with the proper bolt size for the Fox ATS stabilizers.

Zinc coated DOM steel.

NOTE; We’ve changed from the button head bolt to a flat head for better through shaft clearance.

None

None

None$104.97$113.77FREE delivery -

Standard Stabilizer Clamp, Black, 2 Inch ID

FREE deliveryThis fits our 2 Inch Tie Rods – for all model steering stabilizers that use an OE style mounting system with 1/2” bolt.

Black powder coated DOM steel.

None

None

None$104.97$113.77FREE delivery -

Apex Chassis D30 2.5 Ton Tie Rod Kit – Polished Aluminum – JT/JL Non Rubicon

FREE deliveryThis is a complete replacement tie rod assembly kit for your 2018-2022 Jeep Wrangler JL or 2019-2022 Gladiator JT. It includes the tie rod (Polished Aluminum) which is also the adjusting sleeve, and left & right forged steel tie rod ends,plus 2 Ninja Lock Washers.

It does not include the steering stabilizer bracket which you will need to choose in the options above based on the steering stabilizer you use.

FITMENT: This steering kit fits stock Dana 30 axles. For Dana 44 axles, see KIT126. If your Jeep has been upgraded to a Dana 60 axle, we have modifications that can work with that as well, just contact us to order.

Wheels and Spacers: If you run AEV or stock Rubicon wheels, you’ll need a 1.5″ spacer. This kits works with a 17″ wheel with a 4.75″ backspacing or less. We recommend the steering stabilizer be fitted in the stock location, or a relocation kit may be required.

What It Fits: Jeep Wrangler JL (2018-2022), Jeep Gladiator JT (2019-2022) with narrow axles, typically Sport and other D30 axle models.

None

None

$518.10$575.02FREE delivery -

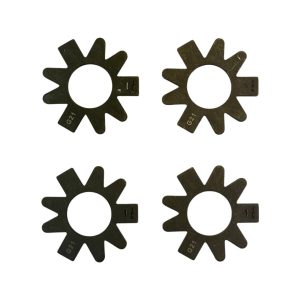

Ninja Lock Washer

FREE deliveryTired of constantly having to re-torque your jam nuts? Our, APEX exclusive, Ninja Lock Washer is designed to secure a jam nut to an adjusting sleeve / rod. Suitable wherever a hex jam nut needs to be mechanically secured onto a hexed adjusting rod. The size indicated is the internal diameter (eg the size of shank it will fit).

None

None

None$31.77FREE delivery -

Tie Rod End

FREE deliveryWhat It Fits:

Jeep Wrangler JK (2007-2018)

This fits the passenger’s side end of the tie rod on our JK 2.5 Ton steering kits, as well as the knuckle end in the JK flip kits.

NOTE: This rod end is not compatible with OE steering systems.

None

None

$132.06$144.52FREE delivery -

$50.40

$52.27FREE delivery -

Apex Chassis 2.5 Ton Drag Link Kit, Black Aluminum (No Flip) – JK

FREE deliveryThis is a complete replacement drag link assembly for your 2007-2018 Jeep Wrangler JK.It includes the drag link (BLK Aluminum) which is also the adjusting sleeve, and left & right forged steel drag link ends, plus 2 Ninja Lock Washers.

FITMENT:This steering kit fits stock Dana 44 and Dana 30 axles in the standard, undermount (not a flip kit). If you need a flip kit (typically more than 3.5 inches of lift, please see KIT138. If your Jeep has been upgraded to a Dana 60 axle, we have modifications that can work with that as well, just contact us to order.

What It Fits:

Jeep Wrangler JK (2007-2018).

None

None$485.00$518.65FREE delivery

- Browse All Products

- Browse By Category

- Accessories

- Engine & Underhood

- Exterior

- Haulers/Trailers

- Interior

- Jeep Overland & Lifestyle Upgrades

- Lighting

- Recovery

- Replacement Parts

- Suspension

- Wheels & Tires

- Winches