-

Standard Stabilizer Clamp, Black, 1.75 Inch ID

FREE deliveryThis fits our 1.75 Inch Tie Rods – for all model steering stabilizers that use an OE style mounting system with 1/2” bolt.

Black powder coated DOM steel.

None

None

None$104.97$113.77FREE delivery -

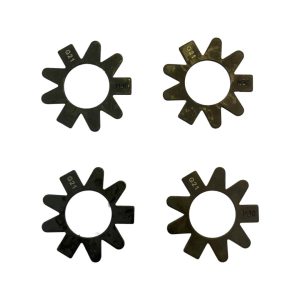

Ninja Lock Washer

FREE deliveryTired of constantly having to re-torque your jam nuts? Our, APEX exclusive, Ninja Lock Washer is designed to secure a jam nut to an adjusting sleeve / rod. Suitable wherever a hex jam nut needs to be mechanically secured onto a hexed adjusting rod. The size indicated is the internal diameter (eg the size of shank it will fit).

None

None

None$31.77FREE delivery -

Apex Chassis 2.5 Ton Drag Link Kit – Steel – NoFlip – JK

FREE deliveryThis is a complete replacement drag link assembly kit for your 2007-2018 Jeep Wrangler JK.It includes the drag link (DOM steel) which is also the adjusting sleeve, and left & right forged steel drag link ends, plus 2 Ninja Lock Washers.

FITMENT:This steering kit fits stock Dana 44 and Dana 30 axles in the standard, undermount (not a flip kit). If you need a flip kit (typically more than 3.5 inches of lift, please see KIT133. If your jeep has been upgraded to a Dana 60 axle, we have modifications that can work with that as well, just contact us to order.

None

None$400.00$431.52FREE delivery -

Fox ATS Stabilizer Clamp, Black, 1.5 Inch ID

FREE deliveryThis fits our 1.5 Inch Tie Rods – with the proper bolt size for the Fox ATS stabilizers.

Black powder coated DOM steel. Photo shows zinc finish.

NOTE; We’ve changed from the button head bolt to a flat head for better through shaft clearance.

None

None

None$104.97$113.77FREE delivery -

Jeep Wrangler JK

FREE deliveryThis is a complete “1 Ton” upgraded replacement FLIP KIT drag link kit for your 2007-2018 Jeep Wrangler JK. It includes the drag link (DOM Steel ) which is also the adjusting sleeve, and left & right forged steel drag link ends, the required taper sleeve, plus 2 Ninja Lock Washers. Note – this KIT requires the drilling of the knuckle.

This KIT is a ‘FLIP KIT’ over knuckle mount which is necessary for lifts greater than 3.5 inches. If you’re looking for a STANDARD under knuckle mount, please see KIT152.

Note: taper sleeves require the knuckle drag link mount to be drilled through with a straight 7/8″ drill bit.

FITMENT:

Wheels and Spacers:If you run AEV or stock Rubicon wheels, you’ll need a 1.5″ spacer. This kits works with a 17″ wheel with a 4.75″ backspacing or less.

Differentials & Mods:This steering system fits stock Dana 30/44 axles. If you have done any major modifications give us a ring at 480-470-5500 or email us at sales@apexchassis.com to discuss. This will fit most modifications, but we want to make sure before shipping. You may also want to discuss with your local Jeep shop to make sure all your modifications are compatible.

If your jeep has been upgraded to a Dana 60 axle, we have modifications that can work with that as well, just contact us to order.

None

None$315.00$344.40FREE delivery -

Steinjäger Sway Bars and End Links Wrangler TJ 1997-2006 End Links, Quick Disconnect Mounting Kit Rear

FREE delivery$25.61FREE delivery -

Ford F250/350 11

FREE deliveryA direct replacement extreme duty Drag Link assembly to replace your underperforming OE steering. Oversized drag link ends, connected by massive DOM tube, eliminates death wobble and tightens up steering under the most extreme conditions. Weak adjusting sleeves are replaced via drag link ends threading directly into the connecting rods, secured by jam nuts and our proprietary ninja lock-washers.

This will change the way your vehicle drives forever!

WHAT IT FITS:

Ford F250 Super Duty (2011-2016) 4WD (except wide track)

Ford F350 Super Duty (2011-2016) 4WD (except wide track)

FITMENT NOTES:

- BDS TRACKBAR – Our drag link is not compatible with the BDS Adjustable Trackbar as the adjuster sleeve on the BDS unit will contact the Apex drag link in operation.

- HIGH MOUNT STEERING STABILIZER – Must be mounted in OE position at taper hole in pitman arm side drag link end. We recommend OE style stabilizers from Fox (Part 985-24-001) and Carli (not through shaft stabilizers such as Fox ATS).

- NOT COMPATIBLE WITH WIDE TRACK

None

None$500.00$534.02FREE delivery

- Browse All Products

- Browse By Category

- Accessories

- Engine & Underhood

- Exterior

- Haulers/Trailers

- Interior

- Jeep Overland & Lifestyle Upgrades

- Lighting

- Recovery

- Replacement Parts

- Suspension

- Wheels & Tires

- Winches